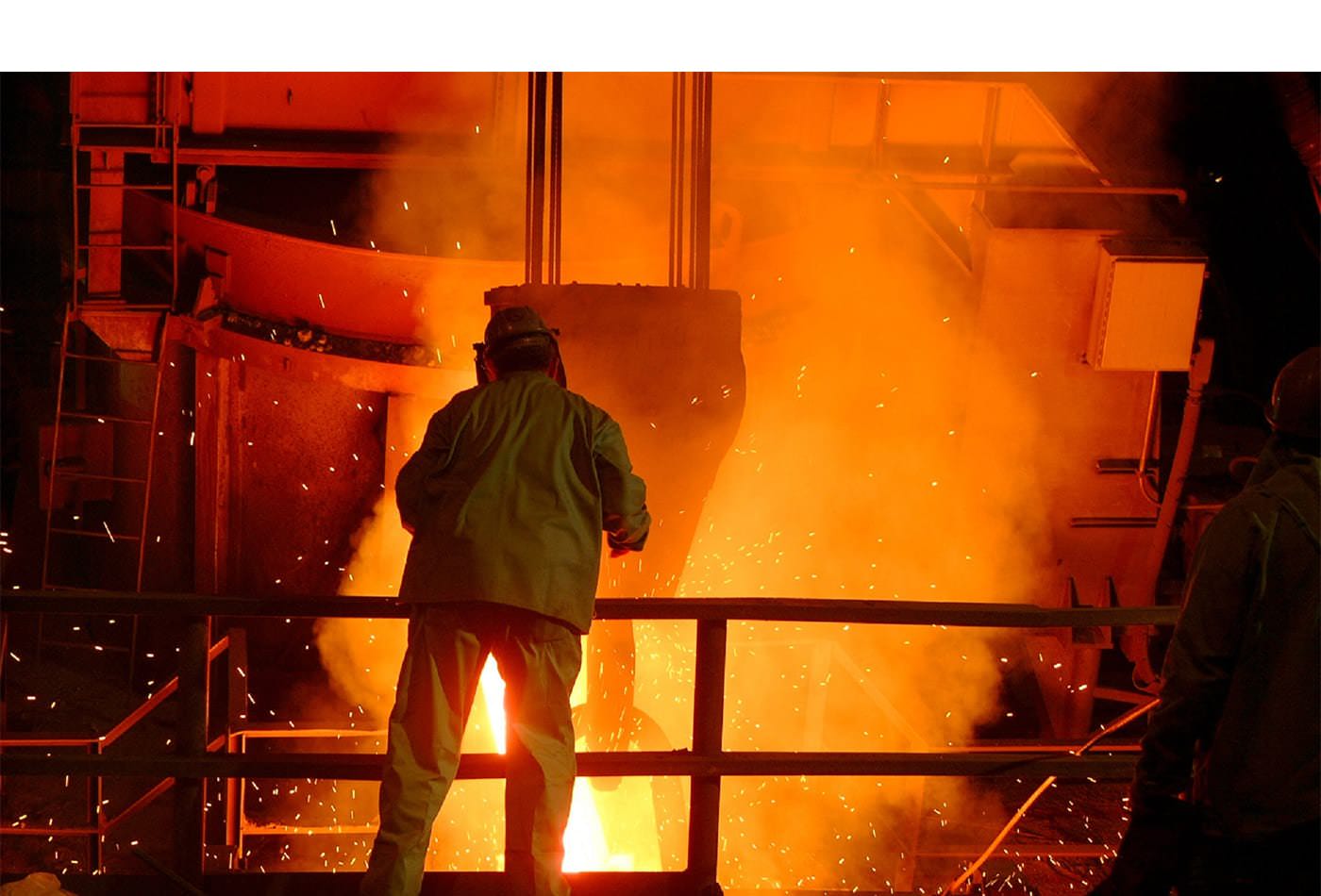

Making metals and forming them into products not only takes place under high temperatures but can also be extremely delicate, requiring the finest of processes and equipment. Dosing the wrong amount of material can ruin the batch, breaking off the wrong part of a casting can cause the loss of an expensive part and not properly controlling the temperature of a material can result in an entire process being out of control. That’s why companies trust JOEST for high-performance solutions using quality equipment.

For the foundry industry, JOEST offers machines and systems for ´green sand foundry´ and ´no-bake sand foundry´ processes like coolers, conveyors or charging machines. Companies within the steel and metallurgy industry can be equipped with hopper discharge systems, alloying systems for Electric Arc Furnaces (EAF) and Ladle Furnaces (LF) as well as with conveyors for VD and VOD processes.

In steel, non-ferrous metal and silica production Joest offers precision dosing feeders with unmatched precision and capacity. JOEST’s screens can meet the rigorous demands of the industry while continuously outperforming others. Our high-temperature designs are based on vast experience and detailed metallurgical analysis which means our equipment will perform in the long run where other’s fail in the short run.

Your demands inspire our innovation. Talk to us about what we can currently offer you as solutions as well as how we can ably our innovation to meet your future needs

Foundry Industry

Steel Industry

Non-Ferrous Industry